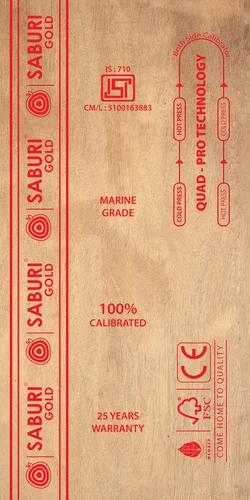

Century Saburi gold

Century Saburi gold

Fast Shipping

Carrier information

24/7 Support

Product & Brand Details

Century Saburi gold

Saburi Club has the ability to withstand extreme weather conditions. That’s why it can be exposed to moisture or humidity for a long duration without any delaminating. You can use this type of plywood for outdoor applications. Due to its high water-resisting property, 710 grade plywood is best suited for applications that are likely to get wet often for a prolonged period, such as bathroom cabinets, kitchen cabinets, etc.

Read MoreSaburi Ply About

Saburi Ply is a dynamic, versatile professionally managed plywood manufacturer in India. We have emerged as one of the reliable and leading manufacturer of superior quality plywood and panel boards in India. It can be used extensively for making furniture, doors, cupboards and much more. Our customers have the facility to avail plywood in various sizes and thickness at affordable price range. Our valued customers trust us and we convert their requirements and concepts into reality.

With a humble beginning more than two decades ago by Chairman, Mr Gajanand Munka in Kolkata, it aims to offer quality plywood and be a trustworthy partner for their plywood needs.

At Saburi Ply we do not merely bank on the existing profile of successful products, but we also continuously introduce futuristic products for the benefit of our customers.

Our sales team is sincere, homely, devoted and we also have long relation with our clients. We aim at maintaining a healthy relation with the retailers and manufacturers.

Saburi Plywood Quality

Saburi Plywood is produced through an automated manufacturing process which ensures uniform quality on every parameter. State-of-the-art machines that ensure perfection at every step, numerically controlled and calibrated temperature, pressure and duration, and automated material transfer helps maintain quality and also conserve energy.

An in-house recycling process ensures maximum utilization of available raw materials, which enables conservation of precious raw materials. A cutting-edge monitoring and quality control system maintains consistent and optimal moisture content, thickness of veneer, quality of veneer and adhesive spread, and all machinery operation. Only after a complete quality check is the material certified fit for sale.