MR PLYWOOD

Fast Shipping

Carrier information

24/7 Support

Product & Brand Details

MR PLYWOOD

Manufacturing Details

Bonded with melamine& Urea Formaldehyde Synthetic resin (conforming to IS:848, 1974).Specific stress-relieving process is employed to keep the product dimensionally stable through a modern tenderizing machine.

Advantage

-

- Durable and Economical.

- Suitable for warm & humid climatic conditions.

- Powder proof, termite resistant and reusable.

Application

Shipbuilding Industry- Shipbuilding, Borne-craft decking, Cargo-covers, Hatch-covers,Catwalks, Bulkhead, Refrigerated ship linings, Life-boats, Yachts.High quality furniture,interior decoration.

Technical Details

Test Results

Moisture Content – 5% To 10%

Glue Sheer Strength (Dry State) – More than 1000 N

Water Resistant Test Water for 3 hours – a) No Delamination after submergine in 70C b) Glue shear Strength more than 800n

Adhesion of plies – Excellent

Specific Gravity – 0.60 to 0.65

Water Absorption – Less than 3%

Screw Holding Strength – More than 150 Kgs

Nail Holding Strength – More than 50 Kgs

PRODUCT DEATILS

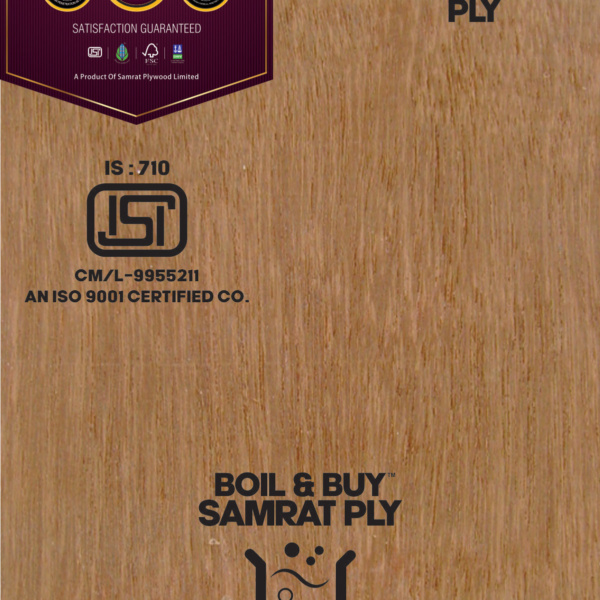

| Variant | Samrat MR Plywood |

| Product | Alternate |

| Grade | MR |

| IS Specifications | 303 |

| Thickness | 6 mm / 9 mm / 12 mm / 16 mm / 19 mm |

| Dimension | All Standard Sizes |

| Warranty | 0 |

MR PLYWOOD KEY FEATURES OF PRODUCTS

Samrat brings you the finest collection of shades, colors and Textures that add soothing and ethereal touch to your spaces. The laminates developed by Samrat gives your space a rich and elegant look.