plywood

Top selling Plywood Brands

13 layer Alternate plywood

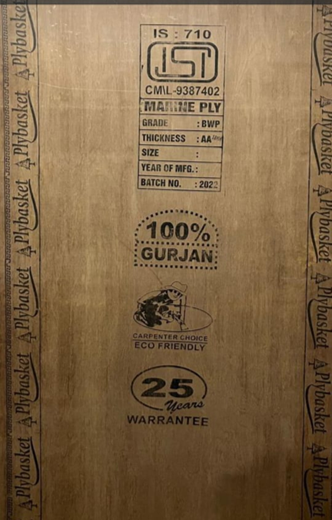

13 layer Red core Gurjan plywood

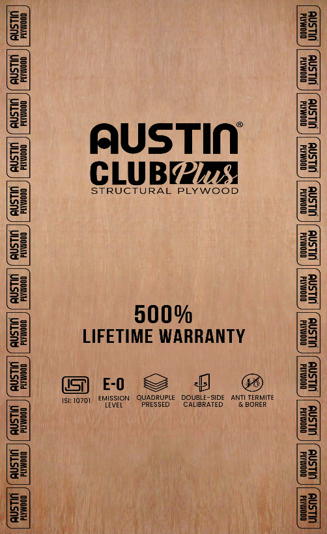

Austin Club plus

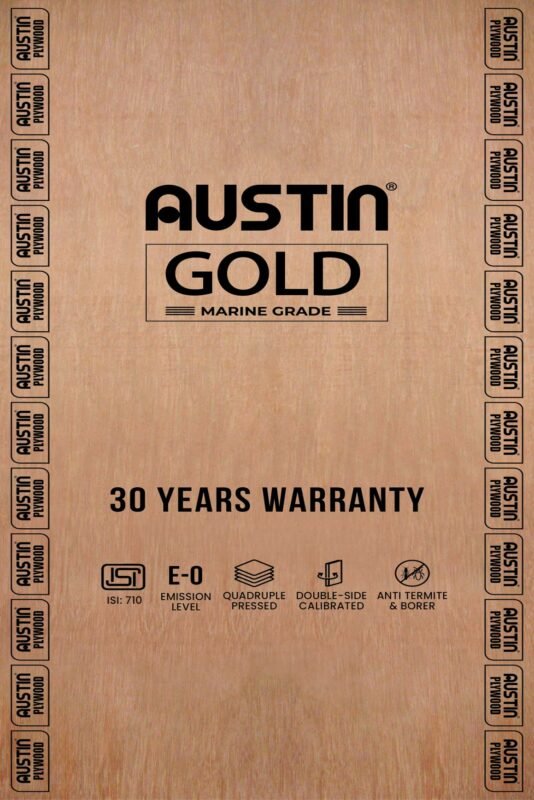

Austin Gold

Austin Lincoln 710

Austin Platnium Plus

Century Architect ply

Century bond 710

Centuryply Club prime

Centuryply sainik Mr

Green Ecotec 710 plywood

Top Plywood Brands

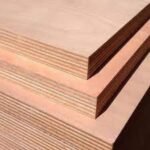

How Is Plywood Made?

The manufacturing process of plywood involves:

Peeling Logs: Logs are peeled into thin sheets (veneers) using a rotary lathe.

Drying Veneers: The sheets are dried to reduce moisture.

Layering: Veneers are layered with alternating grain directions.

Adhesive Application: Synthetic resins like phenol-formaldehyde or urea-formaldehyde are applied.

Hot Pressing: Layers are pressed under heat and pressure to form solid sheets.

Trimming and Finishing: The sheets are trimmed, sanded, and cut to standard sizes.

🔹 Types of Plywood

Plywood comes in various types depending on wood species, application, and moisture resistance.

1. MR Grade (Moisture Resistant) Plywood

Also called Commercial Plywood

Resists humidity but not waterproof

Ideal for indoor furniture and wall paneling

2. BWR Grade (Boiling Water Resistant) Plywood

Can withstand moisture and boiling water

Suitable for kitchen cabinets, bathroom furniture, and semi-outdoor areas

3. BWP Grade (Boiling Water Proof / Marine Plywood)

Made with phenolic resin for 100% waterproofing

Used in marine environments, outdoor furniture, and boat building

4. Hardwood Plywood

Made from hardwood species like teak, birch, or gurjan

Strong and dense — perfect for heavy-duty furniture

5. Softwood Plywood

Made from softwoods like pine or fir

Lightweight and commonly used in construction and packaging

🔹 Common Uses of Plywood

Plywood’s versatility makes it suitable for a wide range of applications:

🏠 Furniture: Tables, chairs, wardrobes, beds, and shelves

🍽️ Kitchen Interiors: Cabinets, countertops, and modular kitchens

🛠️ Construction: Flooring, roofing, wall sheathing, and formwork

🚤 Marine Applications: Boats, ship interiors, and docks

🏢 Interior Design: Wall panels, ceilings, partitions, and decorative laminates

🔹 Advantages of Plywood

High Strength & Durability:

The cross-grained layers distribute stress evenly, making plywood strong and long-lasting.Dimensional Stability:

Plywood resists warping and cracking, even under humidity or temperature changes.Lightweight Yet Rigid:

Easier to handle and install than solid wood.Cost-Effective:

Offers the look and strength of wood at a lower price.Eco-Friendly Options:

Uses less timber than solid wood; many brands now offer FSC-certified eco plywood.Versatile Finishing:

Can be painted, laminated, or veneered to match any interior style.

🔹 Standard Sizes and Thickness

| Size (ft) | Metric (mm) | Common Thickness |

|---|---|---|

| 4 × 8 | 1220 × 2440 | 3mm, 6mm, 9mm, 12mm, 18mm, 25mm |

🔹 How to Choose the Right Plywood

Indoor Use: MR grade

Kitchen & Bathroom: BWR or BWP grade

Outdoor & Marine Use: Marine plywood (BWP)

Budget Furniture: Commercial plywood

Premium Look: Hardwood or calibrated plywood