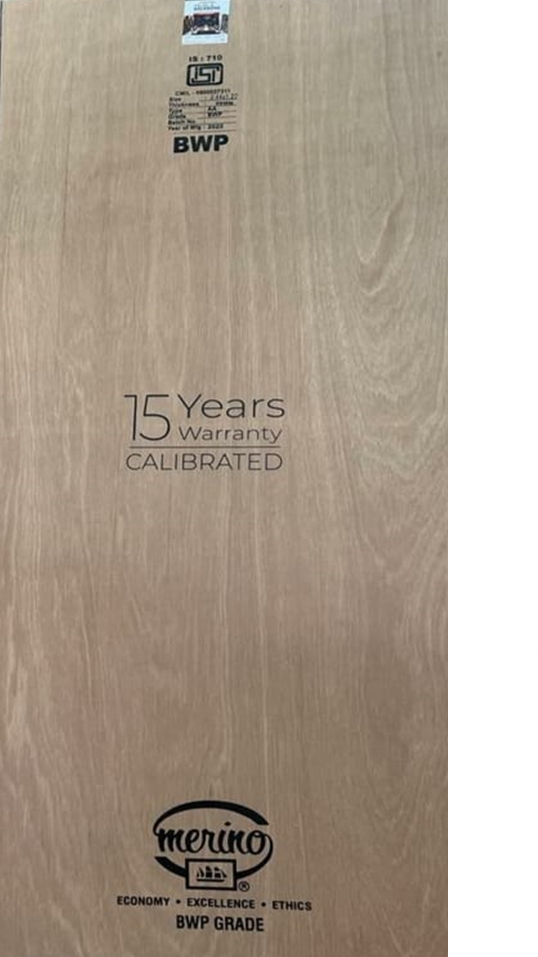

Marine plywood is preferred for outdoor use, given its durability and resistance to the elements. Its multiple layers and high-quality wood make it last 15- 25 years, depending on the type and several other factors.

What Is Marine Plywood?

Plywood is a building material that is manufactured using sheets of wood, compressed and glued together in alternating layers, called plies.

The layers give the flat surface more strength.

The plywood is different that standard ply in the way that it is manufactured, and the grades of marine plywood available.

It is designed to have a resilience against moisture damage (rot) and other outdoor elements, but it is not ‘treated’ specifically. Some plywood is compressed and treated with chemicals that make it more durable to resist damage, but there’s another factor involved in the marine grade.

That is the crucial qualification for plywood to be considered marine grade.

Thanks to this feature, the material is suitable for the boat construction industry, outdoor furniture and home building projects, as it withstands long periods immersed in water, snow, wind and other exposure.

But in addition, marine ply must be constructed from Douglas Fir boards, and a minimum of five layers, bound together with waterproof glue.

Manufacturing Process of Grades of Marine Plywood

Industries create plywood differently, but the goal is to make them durable and high-performance, able to withstand moisture exposure.9

They use the best timber quality for thin veneers, and the layers undergo pressure treatment to create a smooth exterior.

Next, they press the plies using strong waterproof adhesives and use quad-press technology, which guarantees powerful bonding and no gaps in between.

Using the best wood and adhesives results in the famous high-performance Marine plywood.

Features of Marine Grade Plywood

Marine Plywood Near Me

You may ask what makes Marine ply, and the following are the main qualities of the material.

- It can maintain its structural integrity even after prolonged contact with water.

- Its surface is moisture-resistant thanks to the special phenolic plastic used in its construction.

- The sleek surface without pores keeps off the water, which causes delamination in standard plywood.

- It is very flexible and ideal for interior and exterior use or where there is frequent contact with moisture.

- Manufacturers use quality adhesives and modified resin to keep it water-resistant.

- It is the sturdiest and most durable plywood and maintains its integrity regardless of application.

- Given the above impressive qualities and the manufacturing process, marine-grade ply is generally more expensive than standard versions.