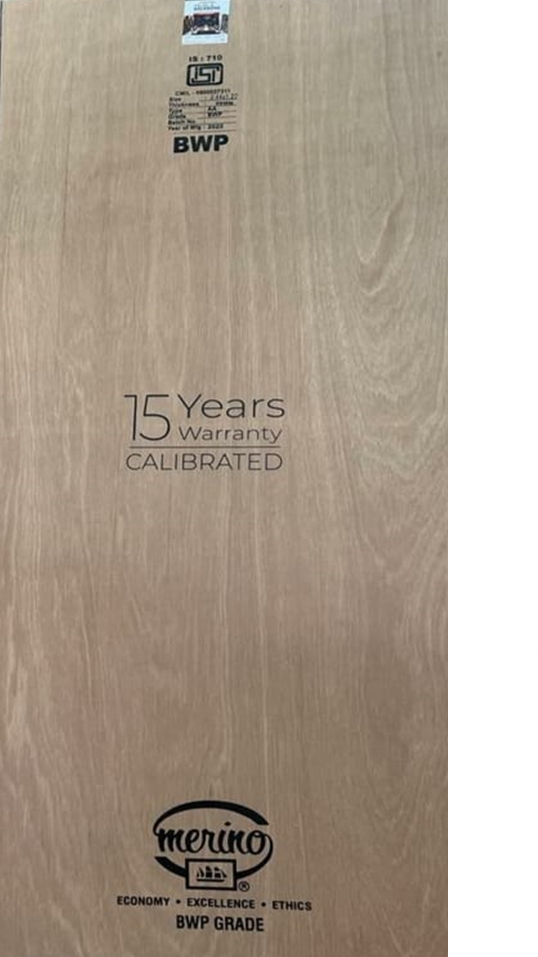

Marine plywood is the highest graded plywood in the plywood industry. This means that the quality of marine plywood is best among all kinds of plywood. The IS grade of marine plywood in India is IS710. Marine plywood, in layman language, is generally BWP or boiling waterproof plywood.

Marine grade plywood is a high-grade quality hardwood panel that is made by alternating sheets of veneer such that the grains alternate in the process of lamination. The veneer or plies are bonded by waterproof glue under heat and pressure to produce a marine grade plywood type that is can withstand snow, moisture, and rain.

Marine grade plywood was created by Dutch door manufacturer Cornelius Bruynzeel in the 1930s, and it was used to build boats during World War II. Today’s Marine Grade panels are made of Douglas Fir or Western Larch. While its name may suggest a panel innately resistant to moisture and rot, this is not the case. To achieve rot resistance, a marine grade plywood must be treated with a preservative or sealed with a water-resistant product such as paint, varnish or polyurethane.

Marine Grades Plywood

Marine Grade is most commonly available in a 4’ x 8’ A-B grade panel, meaning the front of the panel is an “A” and the back is a “B” grade. A-A and B-B (“face back”) grades may also be manufactured, though more typically requires a special order and a large quantity for a mill to consider such an order.

Marine Grade panels may also be finished with Medium-Density Overlay (MDO) or High-Density Overlay (HDO). These overlays of thermoset, resin-impregnated paper fibers create a hard smooth finish resistant to denting and scratching, as well as weather and chemical damage.

Is It Waterproof?

High quality plywood is one of the most popular choices for boat-building and nautical parts and the better quality the plywood, the stronger, lighter, and more flawless it will be. Designed to perform extremely well in high moisture conditions, or environments that will be exposed to moisture for long periods of time, plywood is suitable for finishing and is a first rate option for outdoor furniture near coastal areas., cut to your exact requirements and ready to order at your request.

How To Waterproof Your Plywood

As plywood is a laminated material, it responds extremely well to waterproofing and is also super easy to protect. If you are using an oil based waterproofing option use a soft brush to get the best coverage.

Marine plywood is not waterproof. However, it can tolerate rain, moisture, and snow among other harsh conditions when exposed repeatedly.

Though it is not waterproof, it can resist water damage.

Water resistance

The marine plywood results from a process of laminating plies of veneer together using waterproof glue and under heat and pressure. This results in durable Marine grade plywood having the ability to resist water damage or moisture on repeated exposure. It is, however, not waterproof but can withstand very high humidity.

Different Grades of Marine Plywood

There are five grades of marine plywood. This grading system is useful when determining the quality of marine plywood for specific projects.

A-A grade

This marine plywood comes in two sizes. That is 4 x 8 feet and 5 x 12 feet. It is one of the high-quality plywood types that suit different functions including bathrooms, patios, decks, and boats just to mention a few of its functions. It is ½ inches in thickness and does not have open knots.

A-B grade

This marine grade plywood type almost has the same features as the A-A grade type. The difference is only on the thickness. The A-B grade comes with ¾ inches of thickness and hence is suitable for specific projects such as making cabinets and decks among other uses. Also, it does not have open knots, just like the A-A grade quality.

B-B grade

When it comes to quality, this is one of the lowest and does not serve more sensitive projects like the making of wooden boats. It is, however, useful in projects like patio chairs and tables among other similar projects.

Medium-Density Overlay

The Medium Density Overlay (MDO) is good for most outdoor furniture projects. It is great quality plywood that resists moisture, chemical damage, as well as wear and tear. This grade also has a varying thickness and comes in a standard size of 4 x 8 feet.

Advantages of Marine Plywood

Marine grade plywood comes with several advantages over other plywood types. That is why they are used in most projects that require quality and durable wood like in the construction of wooden boats. Some of the advantages include:

- Comes with an excellent finish that you can use without the need for painting.

- It is flexible and does not crack when pressed.

- It is termite resistant and that makes it last longer.

- There is uniform strength throughout the plywood.

- Useful in many outdoor projects due to its good density and resilience.

- A hard and dense outside layer helps in resisting impact.

Disadvantages of Marine Plywood

Despite the many advantages, marine-grade ply also has its weak side. The first one is the price, of course, due to the quality, the price is way more compared to the regular plywood. The other disadvantage is that:

- It is not waterproof. It is just resistant to water damage.